Challenge

Our client designed a decommissioning Conductor Recovery System for installation on a Norwegian offshore platform. They required a lifting solution to manoeuvre saws, drilling and pinning tooling into position on a system prior to pipe recovery, without relying on platform cranes.

Power and control solutions were required to operate the entire system. We had to consider platform footprint and the high flows and pressures required by such a system that could surpass platform supply. The system offered a Safe Working Load (SWL) lifting capacity of up to 300 metric tonnes supplied via hydraulic cylinders, and the client wanted a solution to safely monitor the SWL while in operation. Any equipment provided had to be operable in hazardous areas offshore and be NORSOK compliant with redundancy capabilities.

Solution

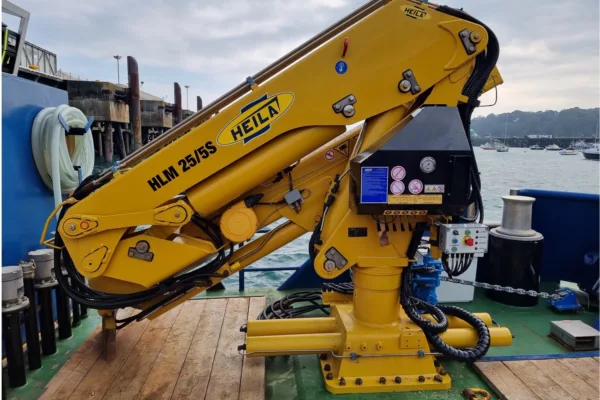

We provided two fully foldable, rental marine cranes converted for use within a Zone 2 Hazardous Environment and certified to NORSOK Z015. The hydraulic overload device on the cranes safely stops all functions when boom structures are overloaded, and load cells were mounted on hooks for monitoring SWL. We supplied a manual emergency pump recovery system to allow the operators to lower the load from the crane if the power supply failed.

We used two Zone 1 45kW Electric Hydraulic Power Units to collectively run the system, with a third provided as a backup to avoid any downtime during operations. We supplied a separate containerised auxiliary tank to cover the high flows and pressures required. Individual framed units allowed for flexibility when installing on deck.

An ATEX Zone 1 Data Logging Jacking Load Unit allowed the client to monitor the entire system lifting capacity via load pins on the system hydraulic cylinders. The unit included an ATEX load display panel, overload warning lights (90%, 100% SWL) and emergency safety cut offs.

We housed a Jacking Tower Control Panel within a DNV 2-7.3 certified lifting frame, to operate various functions including the lifting/lowering jacking circuit, cranes and saw supply, drilling units and two air-operated spiders. We also included supplementary control functions in case of future modifications.